Thin Film Coatings Manufacturing

Solaris Optics provides optical thin film coatings services, including design and deposition.

Thin film coatings are applied on almost any optical element and, together with the substrate, determine the actual characteristics of optical elements. In many cases thin films provide such characteristics as anti-reflectivity, high-reflectivity, resistance to mechanical damage or to high power damage.

Thin films are deposited in chambers. Substrate material (typically several elements) is placed inside a chamber, after which specific coating materials, layer after layer, are evaporated and deposited on elements.

Technology of optical thin film coatings

Solaris Optics owns proprietary software for thin film coating design. Our coating specialists design and optimize all coatings in-house, taking into account also coating chambers parameters.

Once designed and planned, thin films are deposited in chambers. Our optical thin film coating department is equipped with the following coating technologies:

• physical vapour deposition (PVD),

• electron beam (EB),

• ion aided deposition (IAD) and

• plasma ion aided deposition (PIAD).

With the above we are able to deposit thin film coatings with up to about 100 layers. Some specific coating examples we produce, include:

• Anti-Reflection coatings (AR coating) ,

• High-Reflection coatings (HR mirrors),

• Polarizing coatings ,

• Optical filter coatings,

• Dedicated types of coatings like cut-off, bandpass, gradient coatings, etc.

For more information about specific optical thin film coating application, please browse the menu on the left (or top, if on mobile device), or contact us.

Thin film coating materials

Coating materials are selected according to the required surface characteristics, hence we use a variety of materials for thin film deposition. They can be grouped into dielectric and metallic thin films.

Dielectric thin film coatings, e.g. TiO2 (titanium dioxide), SiO2 (silicon dioxide), HfO2 (hafnium dioxide), ZrO2 (zirconium dioxide), Ta2O5 (tantalum pentoxide), etc. More on dielectric HR coatings

Metallic thin film coatings, e.g. Cr (chromium), Ni (nickel), Rh (rhodium), Al (aluminium), Ag (silver), Au (gold), Cu (copper), etc. More on metallic HR coatings.

For more information about specific thin film application, please browse the menu on the left (or top, if on mobile device).

Thin film substrates

Typically a customer requests specific substrate material. Some optical glasses used as substrates include Borosilicate, Crown, filter glasses, etc. Also other materials, including ceramics, plastics, metals, can be used as substrates for thin films.

Thin films quality

Solaris Optics is ISO-9001: certified and follows ISO management guidelines. Quality of thin films is controlled and ensured by placing additional, reference samples in chambers in each coating run. The reference sample coating properties are measured by spectrometry after the process.

Working with clients

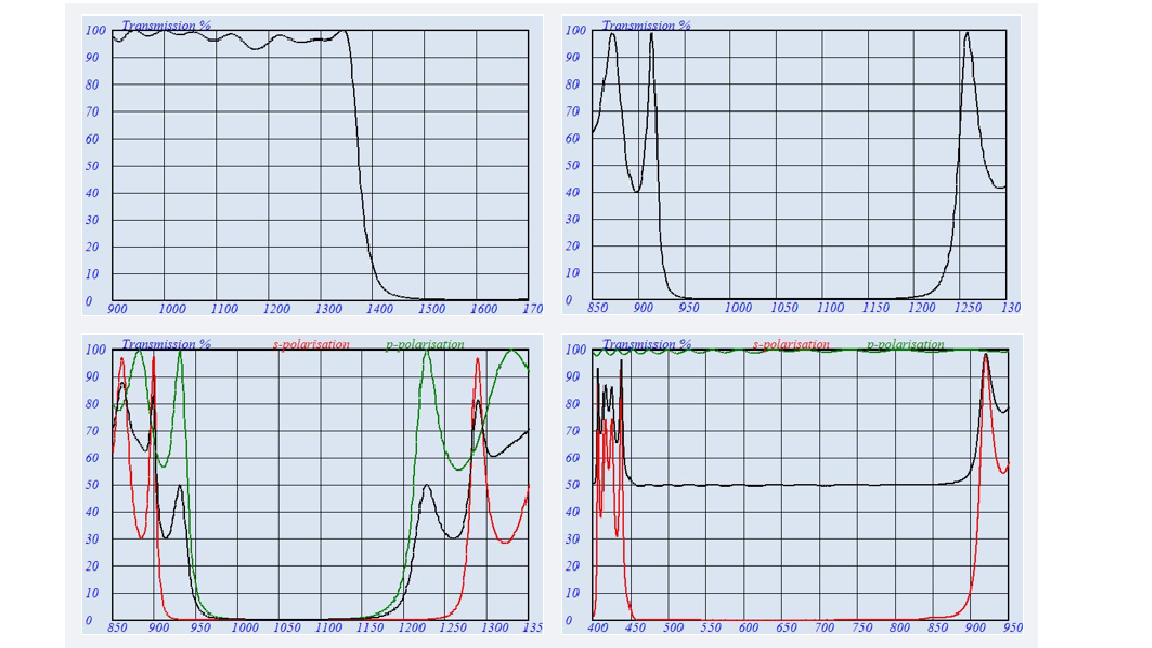

For each design graphs presenting transmission and reflection vs wavelengths are prepared, shared and discussed with clients before the actual coating process begins. Usually a preliminary design is prepared and attached to the pricing offer, which helps to predict the final results and gives an opportunity to discuss clients’ needs and Solaris Optics capabilities.

Please do not hesitate to contact us in case of questions!

***