ar coatings

Antireflection coatings decrease reflection losses from the active surface of optical element. It means that they increase transmission of such optical elements as lenses, prisms or windows, which is very important for designs using more than a few components. Using antireflection coating becomes especially important in the case of optical elements made of material with high refraction index. Optical properties of antireflection coating depend on wavelength, angle of incidence and state of polarization.

Surface reflectance depends on the difference in refractive indices for air and glass (or other optical material).

Antireflection coatings consist of one or more dielectric layers. The kind of materials and thickness of layers used depend on the kind of substrate, wavelength range, properties of incident light and customer requirements.

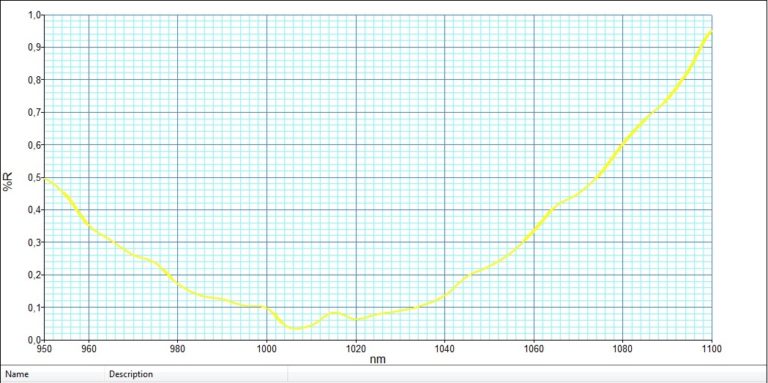

Basically there are two kinds of antireflection coatings: one wavelength and broadband (multi-wavelength). The first one (also called “V”-type) is strongly optimized for one wavelength and recommended for laser optics. The very special item of this kind is two-wavelength coating ( e.g. YAG 532/1064 nm).