optical contact bonding

Optical contact is a bonding method which does not require any glue or cement but instead relies on physical and intermolecular adhesion of the highly polished conformal surfaces. The method creates robust and reliable bond realized solely by intermolecular forces which provides exceptional performance suitable e.g. for applications where gaseous materials, such as adhesives shall be avoided.

Solaris Optics has extensive fabrication and finishing capabilities which ensure our optics meets the strict requirements for flatness and purity necessary to perform optical contact bonding. In the first step, both joined surfaces are physically and chemically prepared for the process to establish required planar surface flatness and smoothness. The flatness of surfaces for contact bonding in Solaris shall be:

- better than 3/0,5(0,5) for surface overall dimensions of less than 60 mm

- better than 3/1(0,5) for surface overall dimensions of 60 mm to 170 mm.

Using technologies such as MRF polishing, we can produce optical surfaces with minimum roughness, form deviation or contamination.

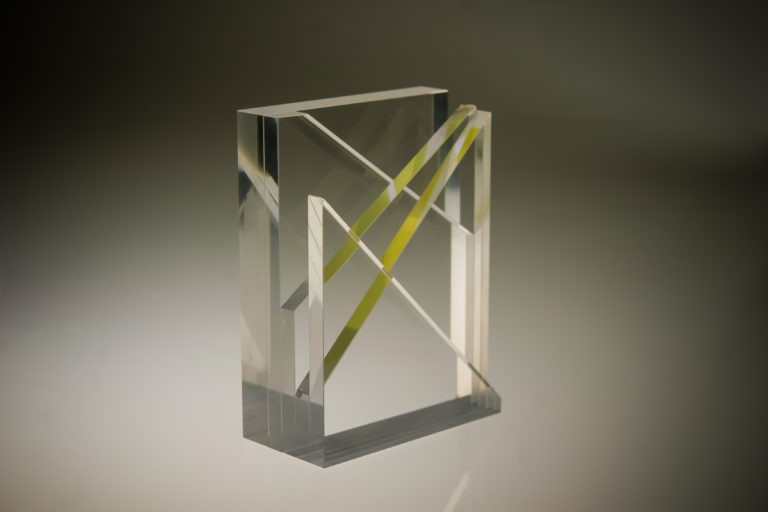

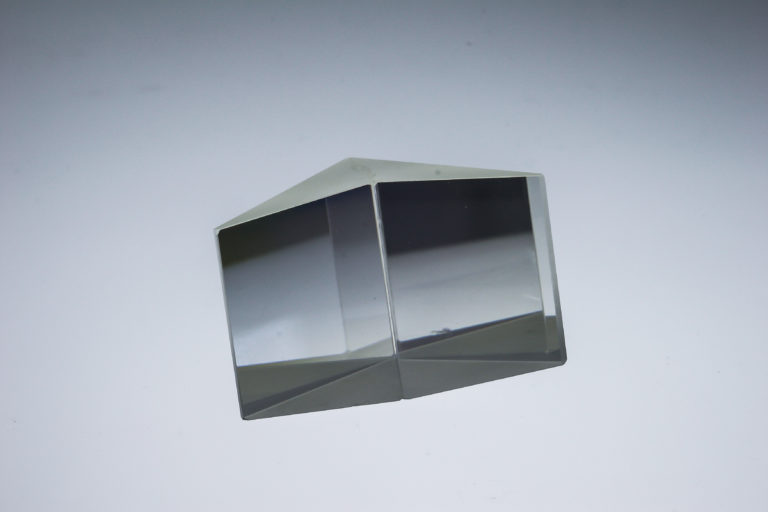

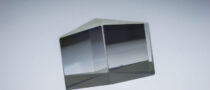

The bonding itself is performed in a room-temperature by accurately adjusting and pressing the surfaces together, in some cases with the aid of chemical activation. Solaris Optics team performs all the operations under strict clean conditions to avoid surface contamination. The components that can be manufactured with optical contact bonding technique include: windows, wedges, prisms, plano-concave lenses and plano-convex lenses.

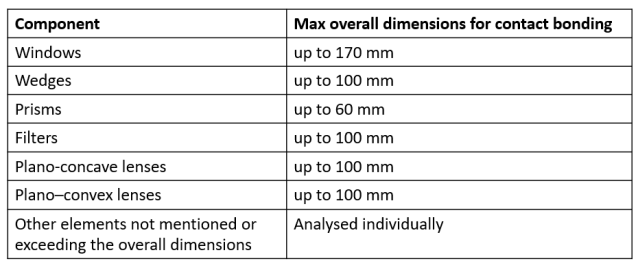

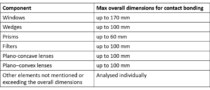

Please see the assisting table showing actual maximum dimensions of contact-bonded elements in Solaris Optics.

By eliminating the need for a bonding agent, optical contact technology provides several advantages over its alternatives. As no additional element is placed in the system, the optically transparent interface does not introduce any losses or distortion which would affect optical performance of the system. This may be of interest in various test and measurement applications, also with micro-optics. Also, lack of gaseous contamination in contact-bonded systems allows for use in space or advanced laboratory conditions, including vacuum environments. It is also safe to process the bonded elements in coating chambers.

Solaris Optics provides contact bonding process tailored to your requirements in company’s optical fabrication facility in Warsaw, Poland. With our extensive machine park and qualified staff, we offer a one-stop design and fabrication service for high-precision optics with over 95% On-Time Delivery (OTD) performance.

Please contact us today, if we can help answer your questions about optical contact bonding.

Learn also more about Solaris Optics capabilities in optical contact bonding, including components, materials, thin film coatings and more in a separate article.

***