optical polishing

Our production is mainly based on the traditional method of polishing and we believe that polishing on tar is the best way to obtain high quality surfaces. This applies not only to glass elements but also to crystalline materials (Ge, Si, CaF2, …)

For polishing we use:

• mechanical grinding and polishing machines, we also have a very large assortment of tools, which allows us to reduce production costs and, consequently, product prices.

• Manual polishers in which we use the delicacy and sensitivity of the human body. The operator holds the tools in his hands and continuously controls the speeds. This requires extremely qualified staff.

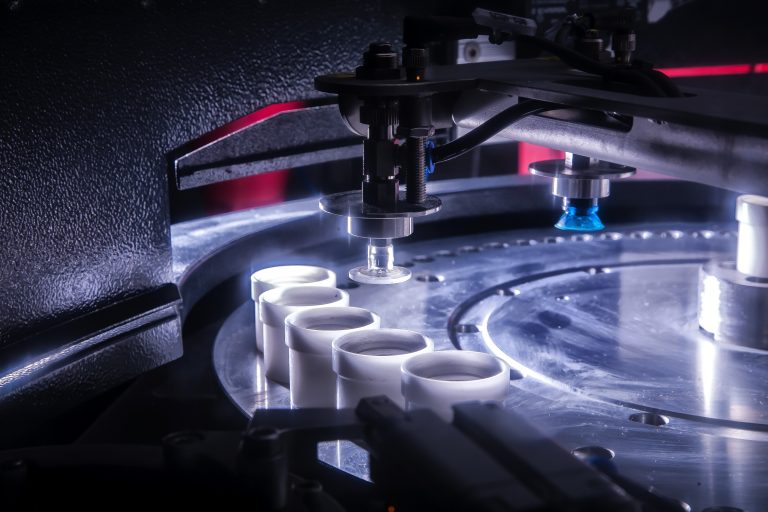

• Corrective polishers using MRF technology. We use this machine to correct deviations of shape (we can change the shape deviation in a short time, eg from λ / 10 to λ / 40). We also use it to correct microroughness (up to 3Ȧ) and to asphyise the surface to a certain extent.