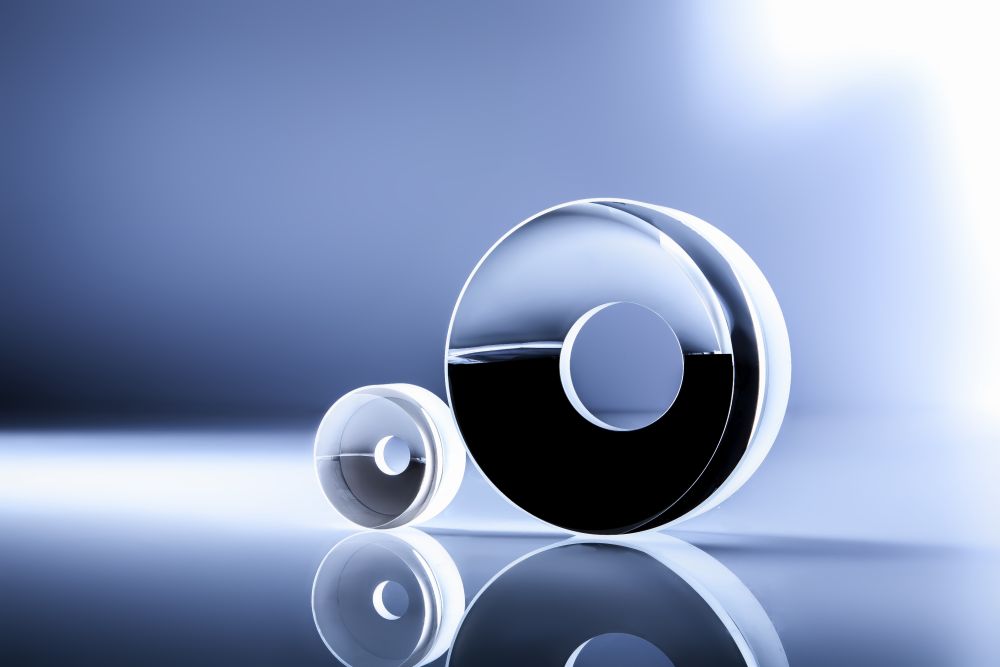

mirrors

Solaris Optics manufactures custom metallic and dielectric mirrors based on customer specifications in our premises in Poland. We specialize in mirrors for high-performance applications that demand high reflectivity, low losses and robustness.

Mirrors are one of the fundamental elements in optical systems, with broad range of applications spanning from laser systems to telecommunication, beam steering and sensors. They are used to reflect whole or part of the beam; create real and imaginary pictures of the objects; magnify, diminish or reverse the image compared to the object and much more. Due to their performance advantages over refractive elements, such as lack of chromatic aberrations, they are preferred solution in many optical system designs.

Applications of mirrors

Metallic mirrors are a preferred option for low-power systems and broadband applications, while dielectric coatings thanks to their high laser damage resistance and configurable spectral range, are well suited for laser systems and optical filters.

The extensive process capabilities in our Warsaw, Poland facility provide a complete infrastructure for mirror fabrication in various shapes, sizes and materials (including BK7, quartz or Zerodur), with metallic or dielectric coatings. A state-of-the-art equipment, strict process control and experienced workforce is dedicated to produce mirrors which can operate under a variety of optical and environmental conditions.

Dielectric and metallic mirror coatings

We produce flat and concave mirrors with dielectric thing films such as TiO2, SiO2, Ta2O5, HfO2 and ZrO2 using cutting edge deposition methods such as physical vapor deposition PVD, electron beam EB, ion aided deposition IAD. Materials used for metallic mirror coatings are mainly aluminum, silver and gold, with additional protection layers for improved mechanical and chemical durability. The key requirements for the design include reflectivity over a specific bandwidth, supported angle of incidence, and level of laser-induced-damage the mirror can withstand. Our experienced staff will assist you with design optimized for spectral ranges matching your application, including IR, UV, broadband or specific narrow wavelength depending on the laser type.

Please do not hesitate to contact us if you have questions regarding our mirror design and fabrication processes!

Learn also about: Mirror coatings

***