Broadband Dielectric Mirrors and Laser Line Mirrors

Solaris Optics manufactures custom dielectric mirrors in our premises in Poland.

Dielectric mirrors, sometimes called also Bragg mirrrors, can be divided according to application and reflected spectrum into broadband dielectric mirrors and laser line dielectric mirrors. Split into broadband and laser line is not very sharp though and the actual mirror characteristics depend on a specific application.

Broadband dielectric mirrors typically reflect a wide spectral range, where wide can mean either 30 nm (e.g. ultraviolet 220 nm to 250 nm), 120 nm (e.g. visible 420 nm to 540 nm) as well as 350 nm (e.g. infrared 750 nm to 1 100 nm) or e.g. entire visible range.

In Solaris Optics we manufacture and design mirrors with dielectric layers, where the actual reflectance range, but also all other specifications are as requested by our clients.

Laser line mirrors are dielectric mirrors meant for a specific laser application, hence for a specific wavelength or wavelength range. They typically have high reflectance in a narrow spectral range (design wavelength), while reflectance is decreased for other wavelengths, which are allowed to pass through. The design wavelength can be set specific (e.g. 248 nm for KrF Excimer Laser ) or dual band (e.g. 532 nm and 1064 nm, so fundamental and second harmonic wavelength of an Nd: YAG laser) or quite broad (e.g. 520 – 647 nm for Kr-Ion lasers).

Solaris Optics is not limited by catalogue spectral ranges and sized as we manufacture laser line mirrors according to customer needs and specifications.

In Solaris Optics Bragg mirrors can be manufactured for operations at angles of incidence AOI from 0° to 55° for custom wavelength ranges, custom shapes and surfaces. For instance we manufactured an aspherised cylindrical mirror with the help of our MRF technology.

Typical substrates for dielectric mirrors include BK7 (N-BK7, borosilicate) or quartz (fused silica). In more demanding applications, e.g. where heat may be induced, low thermal expansion glasses shall be considered, such as Zerodur from Schott, Pyrex or ULE from Corning.

Materials for dielectric thin films include mainly oxides, such as titanium dioxide TiO2, silicon dioxide SiO2, tantalum pentoxide Ta2O5, hafnium dioxide HfO2 , zirconium dioxide ZrO2 , etc. The choice of specific mirror substrate and thin film materials depends on required mirror characteristics, including reflection spectrum, required reflectance, costs, etc.

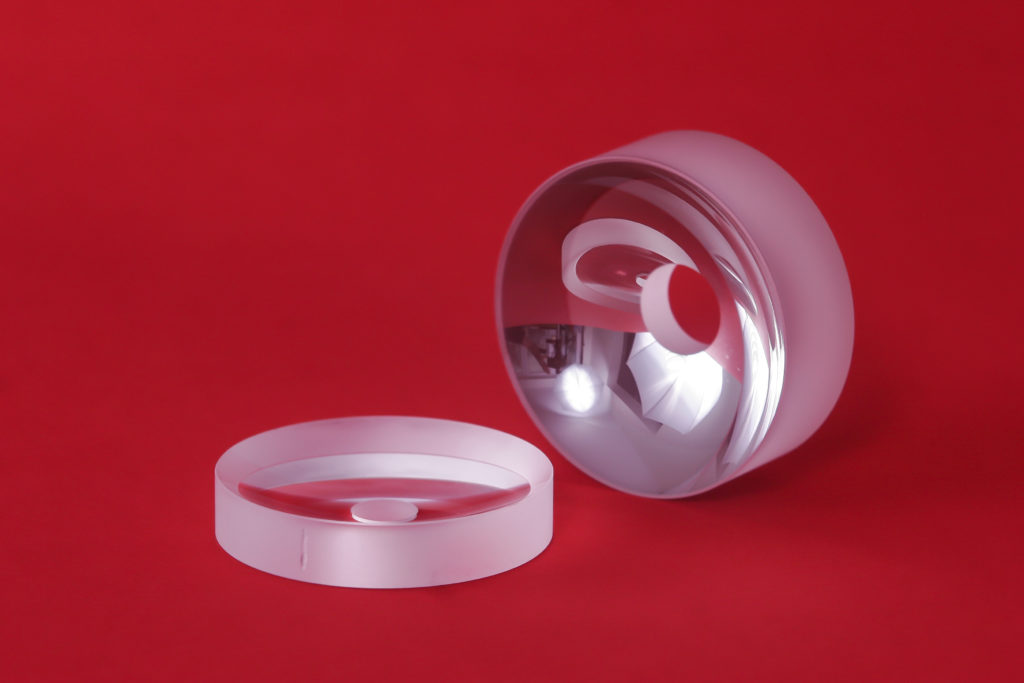

Surface of a Bragg mirror can be shaped according to customer request, e.g. plano, plano-concave, plano-convex, concave-convex, cylinder, as well as more advanced shapes, such as, but not limited to, the aforementioned aspherical mirrors or aspherized cylindrical mirrors.

Solaris Optics thin-film department uses such deposition methods as physical vapour deposition (PVD), electron beam (EB), ion aided deposition (IAD) and plasma ion aided deposition (PIAD). For more information about our thin-film services click here.

Below we provide more information about dielectric (Bragg) mirrors, including fundamentals, typical features, applications, advantages and issues.

Fundamentals of dielectric mirrors

A Bragg mirror is made of a substrate material covered with dielectric optical layers. The layers are designed to achieve high reflectivity (e.g. above 99.9 %) within a specified spectral range.

The number of dielectric layers applied for a mirror starts from 19 and can reach up to 100 for required mirror characteristics. Dielectric thin films show low thermal conductivity, they are electric isolators and, when looked at, are simply transparent.

The reflectance of a Bragg mirror is obtained by fine-tuning such features as number of thin films, thin film thicknesses and refractive indices. Reflectance is induced by a phenomenon of constructive interference.

Typical features of dielectric mirrors

Broadband and laser line dielectric mirrors, given their fundamentals, exhibit the following typical features:

- high reflectivity

- limited spectral range, which can be broadened with special techniques

- low power loss of incident radiation

- high damage threshold, both mechanical (e.g. for scratches) and optical (e.g. for high power laser)

- changing reflectance properties with the angle of incidence

- changing reflectance properties depending on polarization

Typical applications – laser line mirrors

Typical features of dielectric mirrors make them a perfect match for laser applications. Hence typical applications include UV, VIS, NIR and IR, fixed or tunable-wavelength lasers:

- Titanium-sapphire lasers Ti:Sa (first, second, third harmonic)

- Dye lasers

- Excimer lasers XeCl

- Helium Cadmium lasers HeCd

- Diode lasers

- Neodynium-dopped YAG lasers Nd: YAG (first, second, third, fourth harmonic)

- Tundstate lasers Yb:KGW/KYW (first, second, third harmonic)

- Krypton lasers Kr-Ion

- Ruby lasers

Laser line mirrors guarantee high reflectivity for the resonator wavelength (e.g. 1064 nm), negligible power loss, fixed properties at a given incident angle, high tolerance to average power and peak radiation power. Bragg mirrors, optimized for a given wavelength are called laser line mirrors.

Other applications of broadband dielectric mirrors as well as laser line include spectroscopy or beam-splitters.

Typical advantages and issues

Laser resonator application presents the main advantages of dielectric mirrors, as described in the previous chapter about laser line mirrors.

On the other side dielectric mirrors may show difficulties when requirements include:

- operation at long infrared wavelengths,

- high reflectance over wide spectral range,

- varying incident angles.

Should you be interested in our dielectric mirror design and manufacturing capabilities, please do not hesitate to get in touch!

***