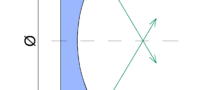

mirror substrates

Solaris Optics manufactures mirror substrates in its facilities in Poland.

Mirror substrates are made of optical materials and are used for reflecting a beam of light. As the light does not pass through the substrate, the optical properties of a substrate material have no influence on the mirror optical properties.

Substrate material is mostly selected due to mechanical properties and working environment of the finished mirror element. If a mirror is designed for working room temperatures then most commonly B270 or N-BK7 materials are used (thermal expansion coefficient for B270 equals 9,5 • 10-6/ K in 20÷300°C, for N-BK7 equals 8,3 • 10-6/ K in 20÷300°C).

If temperature fluctuations must be taken into account, typically Zerodur (thermal expansion coefficient 0,05 • 10-6/ K in 20÷300°C) or quarz glasses (Fused Silica thermal expansion coefficient 0,6 • 10-6/ K within 0÷300°C) would be recommended.

Typical mirror substrate materials: B270, N-BK7, Zerodur, Pyrex,Fused Silica, Borofloat, Silicon, etc

Mirror substrates are usually one-side polished and one-side plane and matt. Mirrors and mirror substrates manufactured in our facilities can reach nanometric Surface Form Accuracy and subnano-roughness.

Please do not hesitate to ask your questions regarding mirror substrates!

Learn more: optical polishing.

***