Optical Materials for Medical NIR Applications

Published: November 2, 2022

Medical infrared (IR) applications refer to the use of infrared light for various healthcare purposes. It includes such medical domains as surgery, skin treatment, spectroscopy or thermography.

Optical spectrum is, in general, divided into: ultraviolet (UV), visible (VIS) and infrared (IR) radiation. Nevertheless, especially for the infrared spectrum, due to many practical and application reasons, the spectrum is further split into:

- Near infrared: 0.75 – 1.0 um (sometimes defined up to 2.5um)

- Short infrared radiation: 1 – 2.5 um

- Medium infrared radiation: 3 – 5 um

- Long infrared radiation: 8 – 12 um

In the following article we focused on some typical near-infrared (NIR) applications for medical purposes and the most commonly selected optical materials for those.

Optical Material Selection for Medical NIR

The process and criteria of optical material selection are a part of a wider discipline of equipment design. Hence, the selected material must fit the general and specific purposes of the equipment to be conceived.

Medical devices, from the application engineering perspective, shall be seen as laboratory-level instruments, given they are used in hospitals, health centers, clinics or aesthetic medicine centers. Such locations are distinguished by well defined and almost stable work environment – lack of shocks, clean surroundings, low fluctuations of temperature. Such devices are predominantly used by trained and qualified personnel.

Laboratory-level working conditions are perhaps the most advantageous from design perspective. They allow to focus on equipment performance parameters, manufacturability, price optimization, ergonomics, etc. They typically do not put any relevant non-standard requirements on optical materials to be used.

Medical Applications of NIR

In absence of major external factors affecting the choice of optical materials, the engineer can focus on the optical matters, i.e. suitability of the optical setup to the given task. The main questions are related to the application itself (e.g. is it related to imaging, lighting, laser beam control) and specification of the required optical system, as well as the wavelengths and power of light.

Within the NIR a review of available publications, shows two main directions, where the NIR spectrum is of use in healthcare: human tissue interaction and NIR spectrometry.

Optical Materials for Laser-Tissue Interaction

The type of interaction of laser light with human skin is diverse and includes: transmission, reflection, scattering and absorption. In majority of cases the most relevant phenomena is absorption, as it effectively transfers the photon energy to tissues. NIR wavelengths are proven very effective in many applications related to human tissue.

The laser-skin interaction can be in simple terms described as depending on the wavelength applied so that the longer the wavelength the deeper into the skin it can reach. This enables applications on the skin surface as well as under the skin, including e.g. hair removal (~700nm), wound healing (e.g. 890 nm), tattoo removal (various visible and NIR wavelengths such as 1064 nm, depending on ink color), vein treatment, hemostasis or tumor necrosis (1064 nm). As listed, depending on specific case a different wavelength is advantageous and within the range the typical laser sources include e.g. Nd:YAG (1064 nm), Alexandrite laser (755 nm), diode lasers (~800-900 nm) or Ruby laser (694 nm).

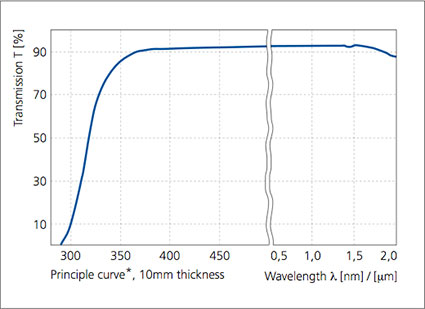

The above wavelengths are crucial in defining the actual optical material to be used. Fortunately for the given ranges, some common VIS transparent materials, such as optical glass, e.g. N-BK7, Fused Silica or IR Fused Silica show also transparency within NIR spectrum. Hence, they are suitable as materials for optical components, such as lenses and optical windows.

Figure 1 Schott N-BK7 transmittance curve for 10 mm glass thickness

Optical Materials for NIR Spectrometry

Spectrometry is an analytical method based on interaction between electromagnetic radiation, such as laser light, and a matter. It is applied to study the contents of materials, molecules of various compounds. In spectroscopy the NIR spectrum range is often defined a bit wider than mentioned above, e.g. from 700 nm to 2500 nm. NIR spectroscopy finds applications for material analysis in pharmaceutical, chemical, food, agricultural and healthcare sectors.

For healthcare applications the NIR range is advantageous as its absorption by water and hemoglobin is minimal, which opens a possibility to study other compounds and diagnose diseases. Some medical uses of NIR spectroscopy include blood testing, identification of proteins or noninvasive monitoring.

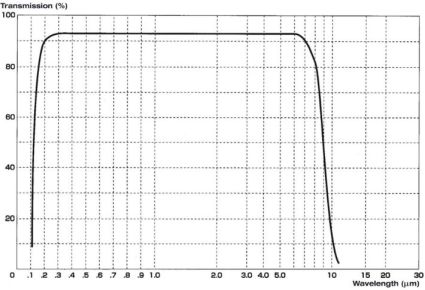

For spectroscopic applications, where the NIR is sampled along the spectrum it is relevant to ensure that the optical materials guarantee high and even transmission (lenses, windows, prisms) or reflection (mirrors) along the spectrum. Hence example optical glasses include IR grade Fused Silica, Calcium Fluoride CaF2, Magnesium Fluoride MgF2 or Silicon.

Figure 2 Internal Transmittance Calcium Fluoride from OHARA

Optical Materials for NIR Medical Applications

Medical NIR applications include mainly non-imaging laser uses. In such cases we have typically rather simple optical setups, which makes optical material selection a bit easier. Materials indicated above, such as N-BK7, Fused Silica, Calcium Fluoride, Silicon and others belong to the “mainstream” of optical materials, used commonly in many applications. It shall be remembered however, that optical elements are usually additionally coated, at least with an AR layer, which comprises of another type of optical materials used in medical NIR applications and was not covered in the article.

Solaris Optics manufactures components, including planar, spherical, mild-aspherical, from all of the above mentioned optical glasses and crystals. We do also thin film design and deposition, and we have experience in the manufacture of optics for medical applications. Should you be interested to learn more, please do not hesitate to contact us.