Spectrometer Prism – Typical Designs

Published: May 9, 2022

Spectrometer prism is a core enabling element of optical spectrometry, which deals with wavelength spectrum analysis. An optical spectrometer deploys a dispersive element – a prism or a diffraction grating, to break down the incoming light into its wavelength components. Modern spectrometers provide high resolution and accuracy in frequency and time domains, operate in a wide spectrum and provide a basis for many modern optical applications in pharmaceutics, food testing, space observation and much more.

In this article we present an overview of main spectrometer prisms – typical prism designs used for optical spectrometry.

The prism was traditionally used for the light dispersion purposes in spectrometry, while the introduction of diffraction gratings and the subsequent development of their quality and efficiency have contributed to their increasing popularity. Nowadays, prisms are still widely used in the low-light applications where inferior transmission of gratings tend to be a blocking point. In such demanding scenarios, prisms exceed diffraction gratings in terms of sensitivity and signal-to-noise ratio. While prism-based spectrometers can offer light throughput efficiency exceeding 90%, diffraction gratings typically offer efficiency of below 70%.

Prism in Spectrometry

Prism are the original dispersion elements used in optics and their use in spectrometry can be dated back to 18th century and works of Sir Isaac Newton.

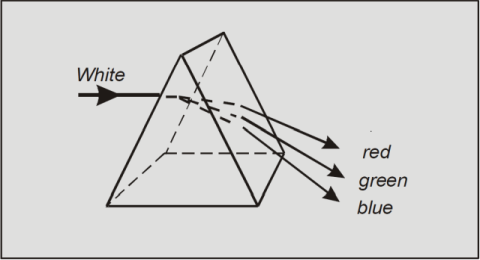

Figure 1 Prism-based Light Dispersion Basics

Prism is a solid structure made from transparent optical material with non-parallel end faces resulting in dispersing of the passing light into its constituent wavelengths. As a result, it is possible to examine the distribution of wavelength in the incident light. Developments in materials and designs have allowed to tackle many limitations of prisms, such as non-linear dispersion, efficiency, UV absorption or thermal stability. Nowadays, optical engineers have a wide choice of prism geometries and materials that offer unique properties and functionalities to match the desired specification.

Spectrometer Prism Geometries

Selecting the optimal prism geometry for the setup involves considering several factors. The geometry and material of the prism have an important effect on their performance, most notably the total deflection angle and linear dispersion at the detection plane.

The most basic type of spectrometer involves an equilateral prism consisting of three equal 60° angles. The dispersion of such prism is a function of its geometry and refractive index. As the refraction coefficient n of optical material depends on wavelength, individual components of a non-monochromatic beam are distinctively refracted by prism’s entrance and exit surfaces and their paths are changed accordingly. As a result, each monochromatic beam will be refracted by a specific angle from its original direction. Many modern prism spectrometers usually use prisms in series to address dispersion in the optical system and enhance the angular spread of the beam.

The alternative is an uncoated Littrow prism, typically a 30°-60°-90° prism which is easier to manufacture but offer a narrower dispersion range. The design takes advantage of the arrangement in which the light entering the element at the Brewster angle experiences a strong dispersion.

Another example is an objective prism, which is defined by a small apex angle but a large size. Its inherent advantage is a wide field, making it possible e.g. in space observation to capture the spectrum of large number of stars at the same time.

Materials of Spectrometer Prisms

The choice of dispersive material is as important as prism geometry when designing a spectrometer. The material needs to exhibit strong change of refraction indexes across different wavelengths. Also, selecting the optimal material depends heavily on the spectrum to be measured. Optical glasses such as BK7 or flint glasses usually cover the complete visible range, while the common IR-compatible materials are zinc selenide, germanium or silicon. For the measurements in UV range, fused silica or quartz prisms are mostly deployed. Additional anti-reflective coatings can enhance performance of the prism in the desired spectrum region.

Manufacturing of a Spectrometer Prism

Since their discovery dispersion prisms have been widely used to split light into its spectral components and thanks to their efficiency and broad bandwidth are still relevant in the field of spectrometry. Please note the quality of a spectrometric system will largely depend on the quality of the components used. Manufacturing of high-precision prisms to be used in spectrometry demands strict tolerances and accuracies. New technologies, such as Magneto Rheological Finishing (MRF) allow to produce exceptionally smooth optical surfaces with figure error as low as ~1 nm RMS.

Solaris Optics manufactures various prisms in its manufacturing facilities near Warsaw in Poland. Please contact us if you wish to learn more about high-performance prism manufacturing capabilities of Solaris Optics.

***