Super Tele-Objective for Earth Observation

Tele-objective is an optical lens system that allows to achieve focal lengths longer than the lens itself. It enables viewing objects in high resolution from a long distance. Such a mix of features is much appreciated in photography, but also in other fields, including e.g. Earth observation.

A consortium of Polish entities, led by Solaris Optics, has recently reported results of a joint project for the European Space Agency (ESA). The project was issued within Polish Industry Incentive Scheme, which is an ESA program aiming at ramping up cooperation with Polish industry.

The aim of the project is to design and build a demonstrator of an Earth observation optical system. A system that shall be operated on an Earth orbit in the future.

The Space Challenge

Space equipment typical requirements, such as light weight, small size and rigidity, are binding also for the tele-objective design. Requirements towards optical performance of the tele-objective include high resolution from a long distance, high image quality, as well as a specific spectral range (wavelengths longer than 450 nm and shorter than 700 nm hence covering the visible light). The design distance between the lens and the low Earth orbit (LEO) was 540km.

Hence the overall challenge and question was, whether all the initial requirements can be met on the design and, later, manufacturing domain. The ESA project started with Phase 1 – design & modelling. Depending on Phase 1 results, Phase 2 – building a demonstrator, can be ordered.

Consortium for Space Tele-Objective

Solaris Optics took a leadership role in a consortium cooperating within the ESA project. The other partners include Space Research Centre (CBK) and Institute of Electronics Materials Technology (ITME). The roles of consortium partners were assigned as follows:

– Solaris Optics – project lead, design, modelling and manufacturing of the tele objective. Additionally the tele objective shall be integrated, assembled and optically tested by Solaris Optics.

– Space Research Centre www.cbk.waw.pl is responsible for design and manufacture of mechanical elements of the tele objective, its integration, mechanical and environmental testing.

– Institute of Electronics Materials Technology www.itme.edu.pl task was to manufacture and design of large area diffractive elements, as well as integration of the tele objective.

Super Tele-Objective Optical Design

On the concept development stage, Solaris Optics modelled several optical setups, including mirror-based (catoptric), mirror-lens (catadioptric) and lens-based (dioptric). Such analyses showed that optimum tradeoff between dimensions, resolution and image quality can be achieved with a dioptric, refractive design.

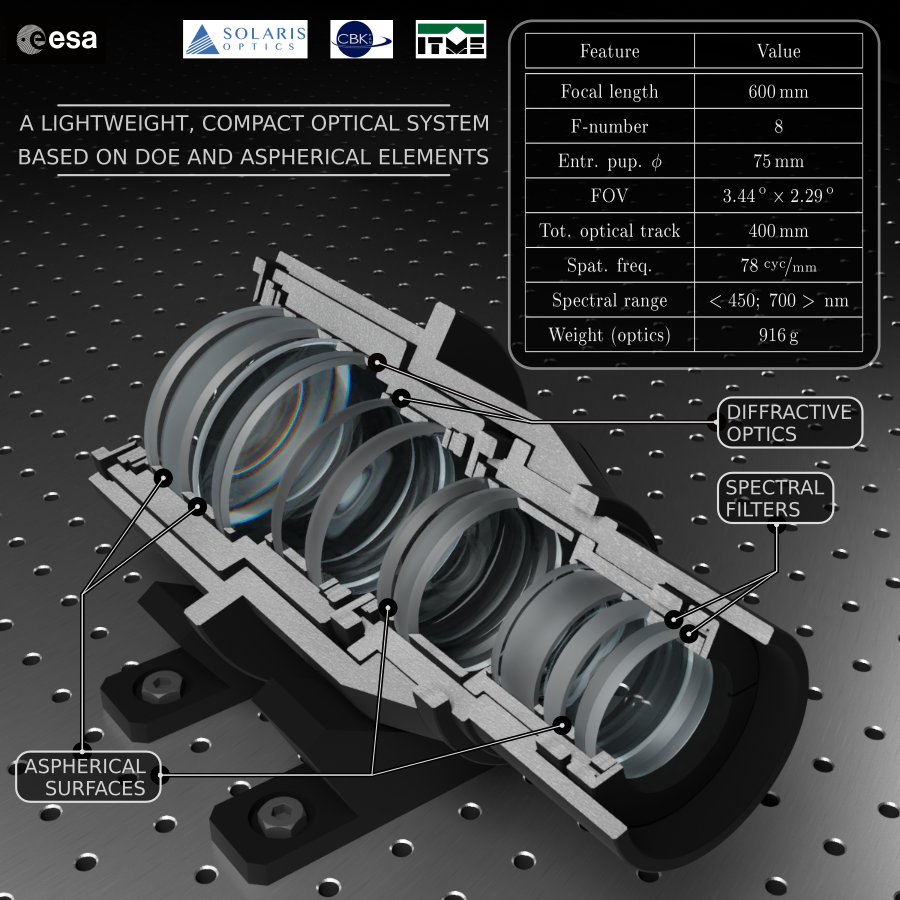

Figure 1 – Super tele-objective design

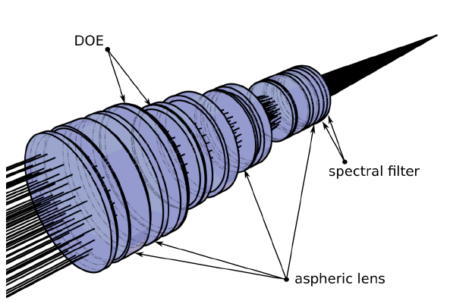

The actual specific outcome was a refractive-diffractive design: a composition of aspheric lenses, diffractive optical elements (DOE) and filters (see Figure 2). Aspheric lenses allow to limit the number of optical elements (hence to limit the total weight) while keeping imaging resolution within acceptable values. DOEs, functionally designed by Solaris Optics, allow to correct the sphero-chromatic aberration with a negligible weight. A set of AR and UV filters secures the required spectral throughput, i.e. wavelengths shorter than 450 nm and longer than 700 nm are filtered out.

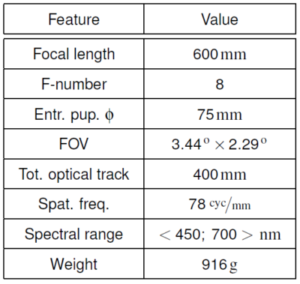

The focal length of the designed optical system (600 mm) positions the tele-objective in a “super” class, hence a “Super Tele-Objective”. Its total achieved weight (the optical elements) is as low as 916 grams.

Optical characteristics of the super tele-objective for Earth observation is presented in Figure 2.

Figure 2 – Super tele-objective parameters

Manufacturing of Key Optical Elements

All the modelled and designed components are to be manufactured by the consortium partners:

– lenses, aspheric lenses and filters – by Solaris Optics,

– DOE components by ITME,

– mechanical housing for the system – by CBK.

Aspheric lenses will me manufactured by Solaris Optics using Magnetorheological Finishing (MRF) technology.

“Our technology team has been successfully using MRF for several years now. Typical application of MRF is ultra-fine corrective polishing of optical surfaces. However in this specific application we use MRF to manufacture the designed aspherical surfaces” tells Jerzy Krężel, PhD, R&D Manager at Solaris Optics.

For spectral filters Solaris Optics will use its Physical Vapour Deposition – Plasma Ion-Assisted Deposition (PVD-PIAD) chambers. PVD-PIAD allows to achieve AR coatings with <1% reflectivity, with materials suitable to space mission requirements.

Solaris Optics Ready to Provide Optics for Space Applications

The project has been recently reported and presented to ESA. The agency executed its Manufacturing, Assembly, Integration and Test (MAIT) Plan Review and requested Phase 2 of the project. Phase 2 includes building a demonstrator and turns the super tele-objective project into production phase. The Phase 2 order is also a successful conclusion of the works delivered by all consortium members.

“Start of cooperation with ESA was a big opportunity for us to show our competence in demanding applications, such as space missions and Earth observation. Ordering of Phase 2 proved our optical design capabilities and shows also ESA trust in our manufacturing capabilities. I am sure we will succeed in the next phase and I am looking forward to it” said Michal Muniak, CEO of Solaris Optics.

Meanwhile the production phase has already started. The lenses, filters and DOE components will be manufactured, assembled, integrated and turned to final tests.

As the final step the consortium will look for opportunities to bring the super tele-objective to the Earth orbit.

***

About

More about imaging optics from Solaris Optics

SPACE RESEARCH CENTRE

The Space Research Centre of the Polish Academy of Sciences activity is dedicated to the research into terrestrial space, the solar system and the Earth using space technology and satellite techniques. Since 1991 it has cooperated with the European Space Agency (ESA). The SRC has also collaborated with NASA (IBEX mission and Chandrayaan mission).

INSTITUTE OF ELECTRONICS MATERIALS TECHNOLOGY

The Institute of Electronic Materials Technology (ITME) is a research, development and consultative institution offering a unique combination of scientific and technological capabilities. The R&D activities of ITME include processing of advanced materials (e.g. graphene, mono-crystals, thick-film materials, opto-, piezo- and superconductor-electronics, etc.) and devices based on these materials.

***